Kwu Tung Station on the East Rail Line commenced construction in September 2023 and is targeted for completion in 2027. Situated between Sheung Shui and Lok Ma Chau stations, the new station will be upgraded into an interchange station for passengers to interchange between the East Rail Line and the Northern Link easily in the future. Watch the Kwu Tung Station Construction Challenge Video to understand how difficult it is to build a new station atop an operating railway tunnel!

Watch more: Explore Kwu Tung Station on the East Rail Line Video (1-min)

Serving the future new development area and aligning with the new development in the vicinity

Kwu Tung Station on the East Rail Line will be located in the town centre of the future Kwu Tung North New Development Area (NDA). It will be the public transport hub in the area, facilitating population mobility across districts. As a new station serving the future NDA, the project team has to ensure high accessibility to the station and maintain its high connectivity with the surrounding community. Since a number of new development projects adjacent to the construction site share a similar construction cycle with that of the Kwu Tung Station project, coordination between projects is required to ensure each project can proceed smoothly. Measures include coordinating the traffic flow at different construction sites to reduce the accumulative impact on traffic in the area.

The design of Kwu Tung Station is well-integrated with the proposed open space outside the station. The station is also equipped with skylights and high canopies, which strengthen air circulation and enhance the natural lighting in the station, thereby creating a pleasant journey for our passengers and a comfortable community environment.

The design of Kwu Tung Station is well-integrated with the proposed open space outside the station. The station is also equipped with skylights and high canopies, which strengthen air circulation and enhance the natural lighting in the station, thereby creating a pleasant journey for our passengers and a comfortable community environment.

Click to join the Kwu Tung Station 3D Virtual Tour

Adopting Common Data Environment (CDE) to update planning and design in real-time for the first time

Kwu Tung Station on the East Rail Line is the first MTR project to fully utilise CDE in order to adapt to changes in planning and design. This approach was recognised with the Bronze Award for the "Hong Kong Construction CDE Award 2023" in November 2023. The CDE platform encompasses digitalised construction information, Building Information Modelling (BIM) and a "chatroom" feature, providing the team with a virtual environment equipped with 3D visualisation. This allows the team to share and analyse building information in real-time, as well as communicate anytime and anywhere, thereby facilitating multilateral cooperation and modifications.

CDE provides the team with an all-in-one platform for monitoring the progress of work easily.

CDE provides the team with an all-in-one platform for monitoring the progress of work easily.

First new station in Hong Kong to be built atop an operating railway tunnel

(Descriptions within the above image are available in Chinese only. The image illustrates the conditions of the ground and underground levels before and after the construction of Kwu Tung Station.)

(Descriptions within the above image are available in Chinese only. The image illustrates the conditions of the ground and underground levels before and after the construction of Kwu Tung Station.)

Building Kwu Tung Station involves a series of large-scale construction works on the existing railway tunnel structure, such as modifying the existing tunnels for station use. These include the construction of platforms at the tunnel level, the concourse in the upper basement, entrances / exits and ancillary facilities on the ground floor, as well as the installation, testing and commissioning of electrical and mechanical equipment and systems, etc.

While constructing Kwu Tung Station, the project team faces three major construction challenges, two of which are related to building a new station at an operating railway tunnel. These include constructing atop the railway tunnel while trains pass underneath in the daytime and carrying out parts of the work inside the tunnel within limited non-traffic hours at night. The third challenge is related to limited working space. To overcome these challenges, the project team is proactively implementing a range of new technologies.

Maintaining the stability of the tunnel structure during construction

Building a new station on top of an operating tunnel is extremely challenging. As the tunnel at Kwu Tung Station on the East Rail Line is a box structure that extends approximately 20 metres (about 6-storeys in height) underground, there must be sufficient weight from the soil above the structure to counteract the groundwater buoyancy to maintain the stability of the tunnel structure.

The new station will be constructed using the "cut and cover" construction method, during which we are required to excavate and remove the soil above the existing tunnel structure. While excavating, the project team has to install a lateral support system to support the weight of soil on both sides to stabilise the ground, control groundwater levels precisely, as well as conduct continuous monitoring of the condition of the tunnel structure to ensure the operation of existing railway facilities is not affected. After the relevant construction works are completed, the ground will be backfilled to cover the tunnel.

Precise tunnel monitoring system to adjust and control groundwater levels

During the construction of the Lok Ma Chau Spur Line, an "under-slab drainage system" was installed by the project team to manually monitor and control water levels. After repeated exploration and testing works, additional measures for tunnel structure protection are being implemented to enhance the precision of groundwater control and monitoring, including the adoption of a new automated groundwater pressure control system. This system can automatically detect water pressure and regulate valves based on a pre-set level for more effective and accurate control of groundwater levels. CCTV cameras are also installed to monitor the water levels in real time. If the water level increases rapidly or reaches a specific threshold, the system will alert the relevant personnel to take appropriate actions promptly.

In the 500-metre-long Kwu Tung Station tunnel section, the project team has installed the Automatic Deformation Management System (ADMS) and more than 200 monitoring points to track the conditions of the tunnel structure in real time. The precision level has reached micrometre accuracy.

In the 500-metre-long Kwu Tung Station tunnel section, the project team has installed the Automatic Deformation Management System (ADMS) and more than 200 monitoring points to track the conditions of the tunnel structure in real time. The precision level has reached micrometre accuracy.

Adopting BIM technology to fully digitalise construction information

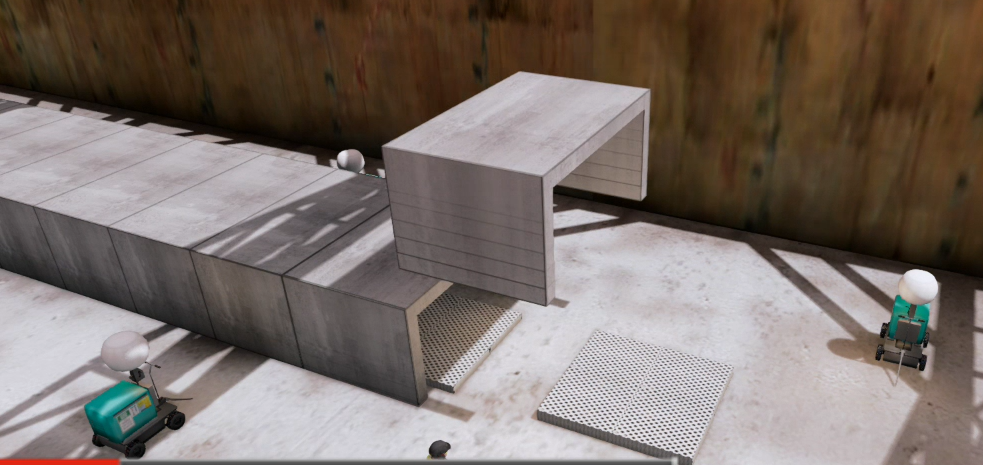

To enhance the overall project efficiency, all teams will preview construction processes on the BIM 3D model, such as where to install the lateral support system underground as well as what materials and weights should be used for the system before excavation to facilitate the construction and work processes to be carried out more precisely and efficiently.

Teams across different specialties are using BIM to plan work processes during the Kwu Tung Station excavation works, including previewing through the BIM 3D model the installation process of the lateral support system (green parts shown in the image above), which supports the weight of the soil on both sides to stabilise the ground.

Teams across different specialties are using BIM to plan work processes during the Kwu Tung Station excavation works, including previewing through the BIM 3D model the installation process of the lateral support system (green parts shown in the image above), which supports the weight of the soil on both sides to stabilise the ground.

CDE and BIM allow the team to detect potential incoordination across disciplines earlier during the design and construction stages, thereby facilitating efforts to overcome the problems immediately to avoid extra time and resources being needed for redesign and planning in the future.

For example, many work processes at Kwu Tung Station have to be carried out underground. In the past, we had to rely on different 2D architectural drawings on site to determine the presence and conditions of underground public utilities (such as water, electricity, gas pipes), and then planned the works to be carried out in the vicinity, such as where to dig by hand to protect underground utilities from being affected during construction. Now, we can use BIM to accurately plan the work processes in advance by viewing the depth and the exact location of the underground utilities, the location of other nearby structures, etc., in 3D visualisation and making real-time modifications.

The team is also proactively using BIM in public engagement to provide different stakeholders with a preview of the internal and external layout of the future station. We have also pioneered the use of 3D building models to demonstrate the simulated station designs to disability groups, providing them with a better idea of the barrier-free facilities of the future station in advance. This move received support and recognition from disability groups.

Implementing 4D photogrammetry to plan construction processes and monitor progress

To accommodate the daily operation of the East Rail Line and nighttime inspection and maintenance, the project team can only carry out various complex construction works for the new station on certain nights of the week during non-traffic hours between the end of train service at midnight and the start of train service the following day. To ensure that the daily train service will not be affected the next morning and to advance the project against time, the project team must first carry out protection works for existing railway facilities before construction, and inspect the condition of the existing tunnels and railway facilities after completing the night shift. To fully manage the project progress, we incorporate a timeline into the BIM 3D model, making the construction schedule and progress clear at a glance, and monitoring whether each process could be completed on schedule through 4D visualisation. 4D photogrammetry is also utilised during construction to assist in verification and progress tracking with interactive charts.

4D graphics allow the team to have a clearer picture of the construction progress. If uncontrollable factors arise during construction where the work process and construction plan need to be modified, relevant updates can be delivered more quickly.

4D graphics allow the team to have a clearer picture of the construction progress. If uncontrollable factors arise during construction where the work process and construction plan need to be modified, relevant updates can be delivered more quickly.

Enhancing the power connection system to increase non-traffic hours for carrying out construction

To increase the non-traffic hours that can be used for constructing the new station, the project team is enhancing the power connection system to achieve a zonal power supply, allowing the power supply system of the Lok Ma Chau Spur Line to be independent from the East Rail Line mainline. Currently, if the project team needs to enter the Kwu Tung Station tunnel section to carry out works during non-traffic hours, they must wait until the end of train services on both lines of the day and the completion of "power isolation" afterwards before entering the relevant location to carry out the works.

In future, upon completion of the cable diversion works, the project team will be able to first "isolate" the Lok Ma Chau Spur Line section's power system independently once its train service for the day ends. After making sure the power supply is safely disconnected, they can then begin construction at Kwu Tung Station, with the section between Sheung Shui and Lo Wu stations continuing to provide services.

Utilising railway transportation for constructing the new station

As the site area of Kwu Tung Station on the East Rail Line is limited to the land reserved for the construction of the Lok Ma Chau Spur Line, the space for carrying out large-scale construction works, positioning machinery and allowing the project team to enter and exit is very limited. As most of the carriageways within the construction site can only accommodate one large construction vehicle, passing bays must be used when more than one vehicle enters or exits. Therefore, depending solely on road transport would significantly impede the progress of the works.

In order to free up more space for construction, materials for the new station will be transported to the Kwu Tung Station construction site by railway via the Lo Wu Marshalling Yard for the first time to save transportation time. The project team will also increase the number of construction locomotives to maximise the utilisation of the railway for transportation of works materials.

The Lo Wu Marshalling Yard will be upgraded to serve the needs of the Kwu Tung Station project, including the construction of a new siding and loading/unloading bay, which will enable construction locomotives to transport construction materials to and from the Kwu Tung Station construction site via the Yard.

The Lo Wu Marshalling Yard will be upgraded to serve the needs of the Kwu Tung Station project, including the construction of a new siding and loading/unloading bay, which will enable construction locomotives to transport construction materials to and from the Kwu Tung Station construction site via the Yard.

Adopting Design for Manufacture and Assembly (DfMA) and Modular Integrated Construction (MiC)

In addition, we have identified suitable processes and components to be prefabricated in factories. The completed prefabricated components will then be transported to the construction site for assembly under the concept of "factory assembly followed by on-site installation", so as to minimise on-site construction procedures, increase work space and shorten the preparation time between design and construction. This process will also reduce the noise, waste, dust, sewage, etc., generated at the site, thereby facilitating the project to be more aligned with the principle of sustainable development.

Prefabricated components will be used in the construction of certain parts of Kwu Tung Station, such as staircase structure, ceiling components, ventilation ducts on the railway tunnel, platform sills, etc.

Prefabricated components will be used in the construction of certain parts of Kwu Tung Station, such as staircase structure, ceiling components, ventilation ducts on the railway tunnel, platform sills, etc.

In order to further enhance site safety and safety management culture, strengthen quality assurance and monitor construction progress, the team is actively promoting "Smart Construction Sites" and applying various smart devices, such as an "object tracking and detection system", smart wearables and VR safety training, etc., at the construction site of Kwu Tung Station, with 5G Wi-Fi covering the entire site area.

Upon commissioning, Kwu Tung Station on the East Rail Line will become an integral part of Hong Kong's strategic development by complementing the future Northern Link to promote the development of the Northern Metropolis.

Note: The station name is a working title only. All drawings and visuals are provided for concept illustration only, and the content is subject to change.