Sustainable Station Features

Innovation and Environmental, Social & Governance (ESG) are embedded into every aspect of the project

The overall station design incorporates elements of sustainable development, with a target to attain BEAM Plus Gold Certification for the project

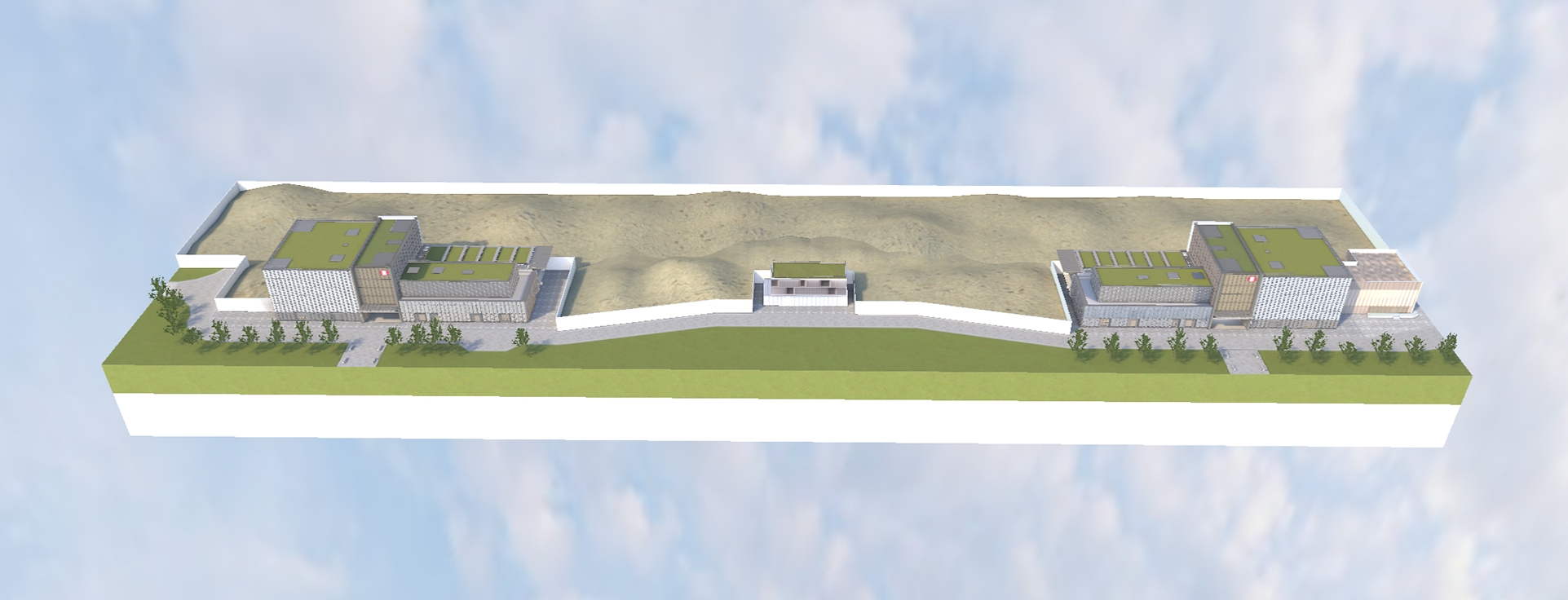

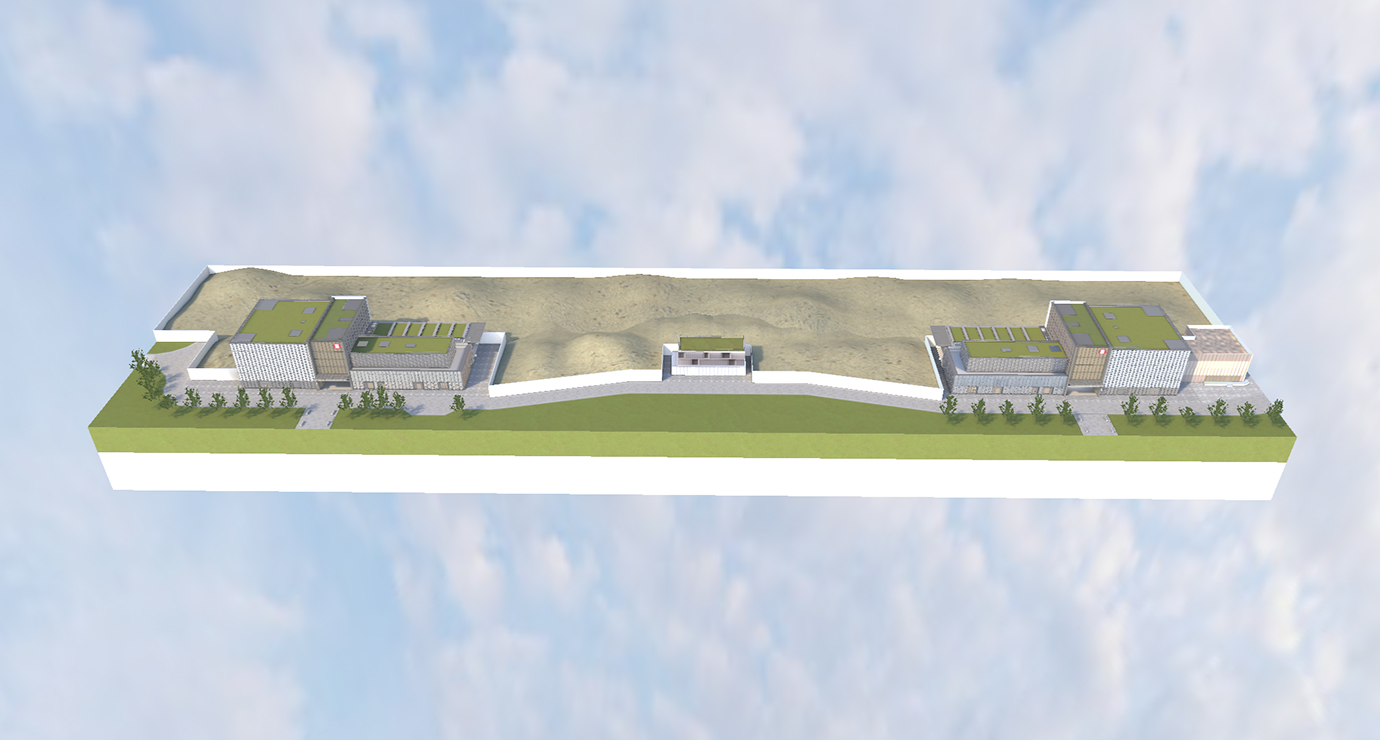

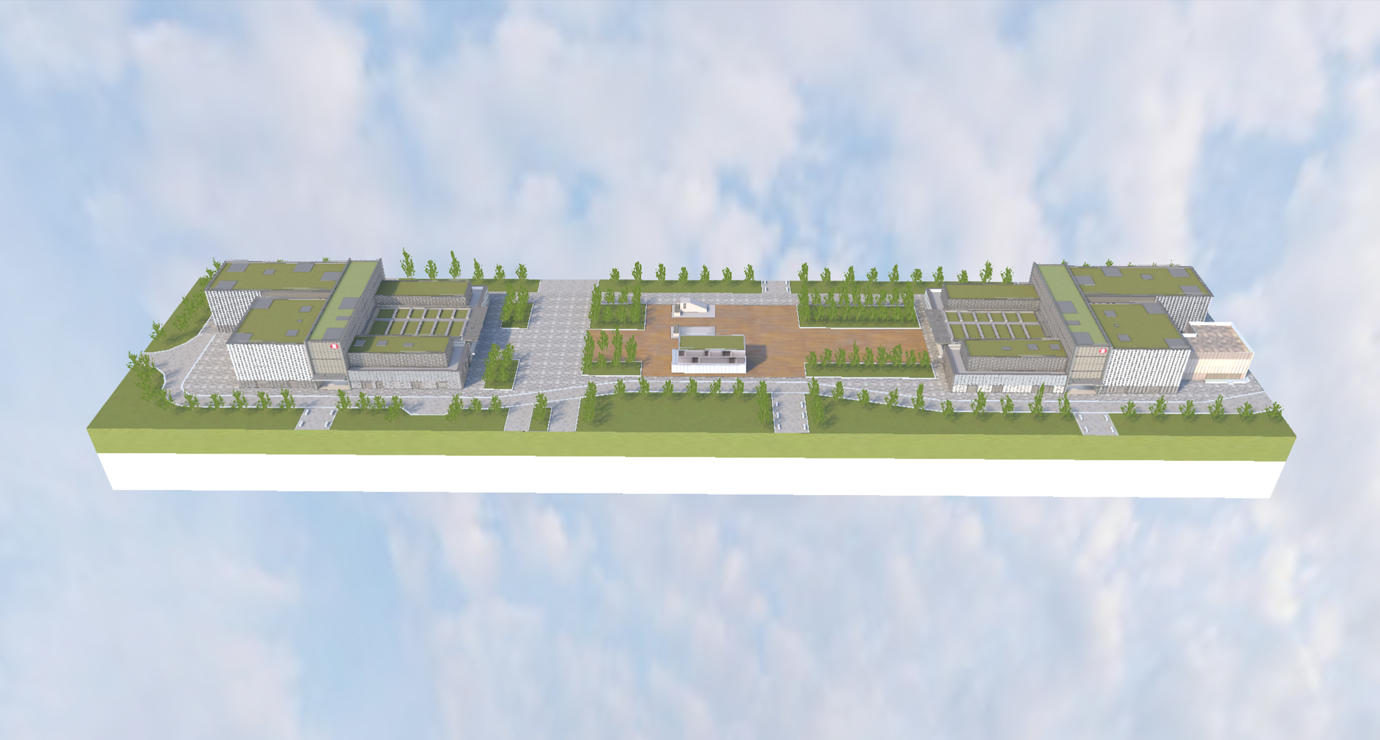

The overall design of Kwu Tung Station incorporates the historical and cultural characteristics, as well as features of the natural landscape of Kwu Tung, aiming to realise the integration of urban and rural areas, as well as traditional and new generations, while promoting railway development in the community. The station design is also well-integrated with the proposed open space outside the station, providing a seamless experience for passengers to enjoy a recreational space after their journey. In addition, the station entrances / exits adopt an open design to align with the proposed natural ventilation and green corridor nearby. The station is also designed with skylights and high canopies, which strengthen air circulation and enhance the natural lighting in the station, thereby creating a pleasant journey for our passengers and a comfortable community environment. Other examples of sustainable features of the station include:

-

Natural Lighting

-

Natural Ventilation

-

Green Roof

-

Neighbourhood Integration

-

Inclusive Design

-

Neighbourhood Integration

-

Inclusive Design

-

Inclusive Design

Caring and barrier-free station facilities, such as passenger lifts, barrier-free accesses and public toilets, will be available at Kwu Tung Station for passengers in need, facilitating them to travel with ease. The station will also be equipped with a babycare room, providing a more comfortable environment for passengers to breastfeed and take care of their babies.

Use of innovative technology to enhance construction quality and work efficiency

Building Information Modelling (BIM) technology has been applied at every stage of the Northern Link project to visualise the railway structures’ internal and external design, making integration and communication on construction works easier. The project team is also actively studying the adoption of the Design for Manufacture and Assembly (DfMA) and Modular Integrated Construction method (MiC) to minimise on-site construction processes, thereby enhancing project quality.